Rubber belts

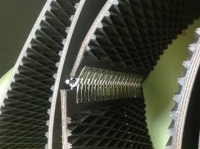

Reko Ltd supplies the first-class rubber transporting belts of the SAVA mark. The transporting belt is composed of the two parts - tractive carrier (body) and covering layer. The covering layer is made of rubber, the tractive body is made of a special-purpose produced fabric. The edges may be protected or open.

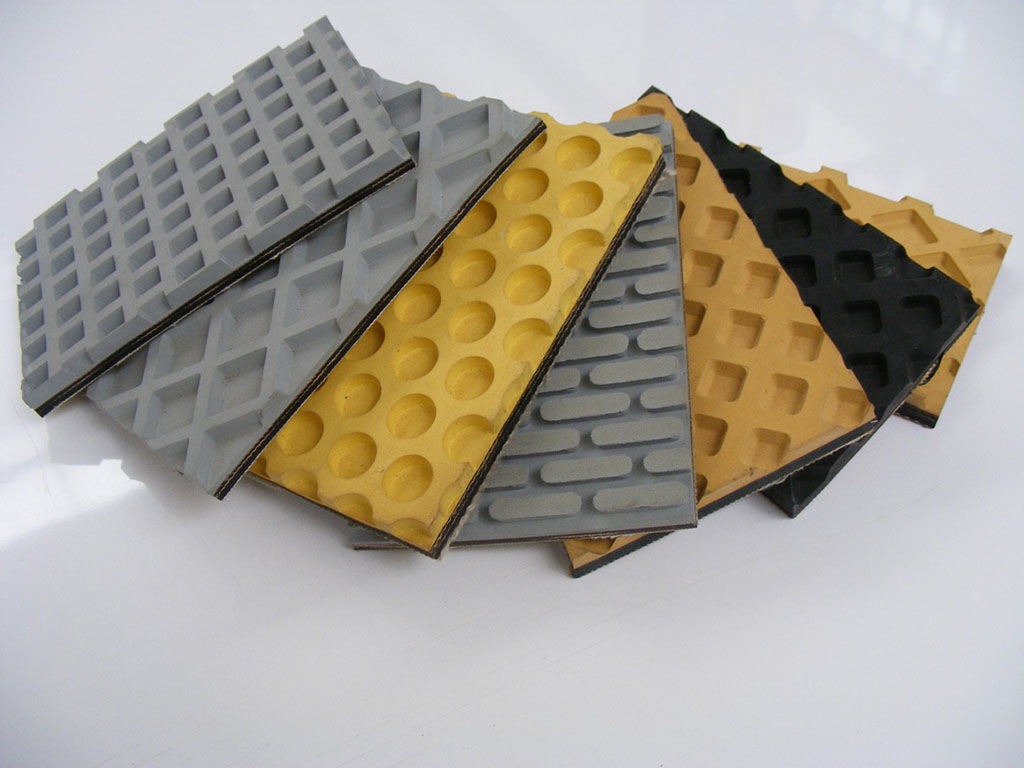

Rubber bands according to the type of rubber covering layers:

NL - Abrasion-resistant bands.

Y - Abrasion-resistant bands, upon the DIN 22102 quality.

ML - Highly abrasion-resistant bands.

X - Extra-abrasion-resistant bands, upon the DIN 22102 quality.

W - than X type abrasion-resistant bands, upon the DIN 22102 quality.

N 17 - Very abrasion-resistant bands, upon the BS(British Standard) 490 quality.

M 24 - Extra abrasion-resistant bands, upon the BS (British Standard) 490 quality.

Grade 2 - Abrasion-resistant bands, upon the RMA (USA) quality.

Grade 1 - Highly abrasion-resistant bands, upon the RMA (USA) quality.

Remark:

All the above-mentioned bands are applicable for transporting the material at 80 °C maximal temperature, at from -25 °C to 60 °C temperature scale. All the types of covering layers are anti-static.

Self-extinguishing bands for the extractive industry:

S - Self-extinguishing and anti-static bands with or without the protective covering layer for usage in the extractive industry.

K - Self-extinguishing anti-static bands with protective covering layer as designated for the extractive industry.

Remark:

They are in conformity with the DIN 22102, DIN 22103, DIN 22104 requirements. You are asked to specify in your order the standards you require.

High temperature-resistant bands:

T1 - Thermoresistant bands. Admissible for temperatures of a transported material up to 100 °C, at short-term up to 120 °C, for outdoor temperatures from -25 °C up to 60 °C.

T2 - Thermoresistant bands. Admissible for temperatures of a transported material up to 125 °C, at short-term up to 150 °C, for outdoor temperatures from -25 °C up to 60 °C.

T3 - Thermoresistant bands. Admissible for temperatures of a transported material up to 150 °C, at short-term up to 180 °C, for outdoor temperatures from -25 °C up to 60 °C.

Remark:

All the types are up to the ISO 4195-1 and ISO 4195-2. In those highly thermoresistant, we recommend the usage of a transporter with the automatic tensioning sysem

Bands partially resistant against oils, greases and higher temperature:

T-type -Thermoresistant bands. Admissible for temperatures of a transported material up to 100 °C, partially resistant against oils and greases. The outdoor temperature from -20 °C to 60 °C.

Oil-and-grease resistant bands:

MOR - Medium oil-and-grease resistant. Admissible for temperatures of a transported material up to 60 °C. The outdoor temperature is from -20 °C to 60 °C.

OR - Oil-and-grease resistant. Admissible for temperature of a transported material maximum up to 60 °C. The outdoor temperature from -15 °C to 60 °C.

- Black-coloured, anti-static upon the DIN 22104.

- Green-coloured and white-coloured, for food industry upon the BGA (Federal Office for Food Industry) XXI - category III/1981, they are not anti-static, having maximum1300 mm width, unprotected edge.

- Made only from the EMF-fabric.

It is our pleasure to render provide you with any other information data based on a factual request, including any other types, standard sizes, band-related outfit, texture etc.